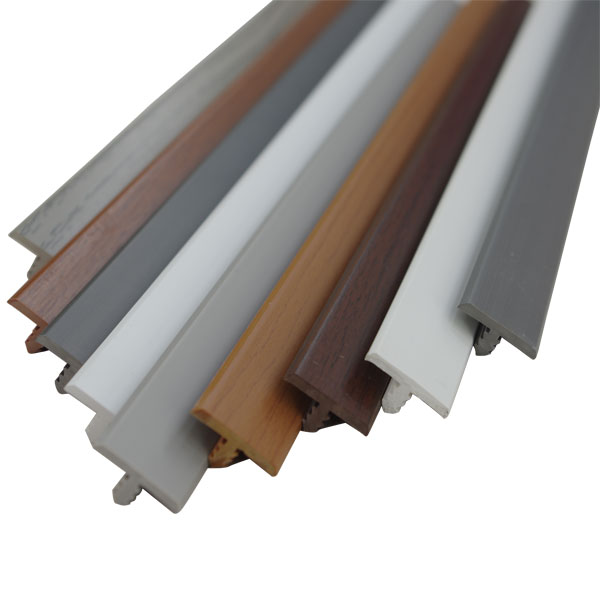

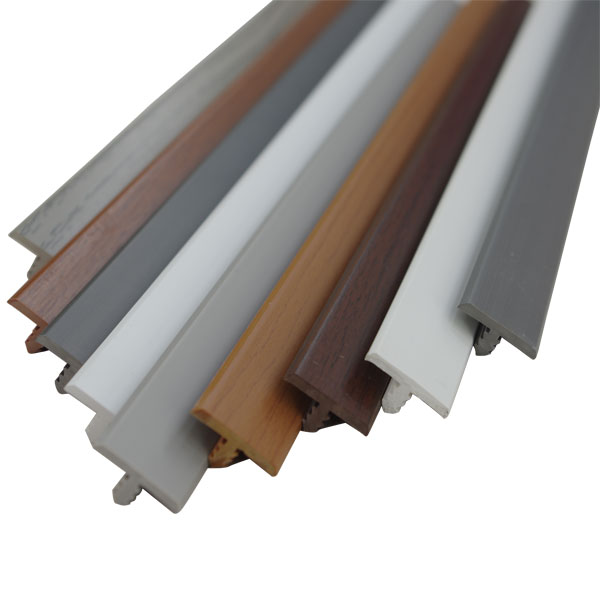

PVC edge banding production

It is on the PVC substrate and then rolled after printing the UV paint to solidify.

The good simulation effect of the wood grain edge bar is that the quality of the ink is good or bad. Now, the price of the ink is 20 yuan / kg -- 160 yuan / kg, and the quality of the ink seal edge is excellent. The simulation effect of the sealing strip is close to the plate, and the printing level is rich, and the color fading is not obvious in three years. At present, the rich printing edge is mainly three color printing, followed by two color printing and one color printing.

Detection method: put the edge strips printed with different printing ink in the strong sunlight for a week, and then compare with the sunlight, we can see that the color of the two kinds of edge strips is different. The wear degree and transparency of the wood stripe are related to the quality of the UV lacquer. The market price of UV lacquer is between 50 yuan / kg - 120 yuan / kg. If the surface of the sealing strip is easily scratched and blur, it is due to the use of inferior UV paint. Sealing strip and plate bonding degree, edge banding and heat bonding effect depends on the quality of the adhesive.

The bonding of the plate and the edge of the edge has a certain requirement on the temperature. Although the hot sol temperature edge hot-melt adhesive barrel at 200 o C, 180 o C, but the hot sol coating plate with edge strips after rolling bonding points 20CM - 30CM distance. Because the temperature of the workshop is low and the heat dissipation is fast, the temperature of the bonding point between the plate and the edge bar is actually below 120 C, so the bonding effect is not ideal. At this time if the use of gum is not good is more easy to open (the gum market price: 18 yuan / kg, 50 yuan / kg). The way to solve this problem is that because the cutting saw from the low temperature place will affect the adhesive effect because of the low side temperature of the plate, so we must keep the indoor temperature of the workshop above 15 C, and add a thermostat on the edge plate of the edge sealing machine.