Factors affecting the quality of edge

On the edge of the process, the impact of edge quality of the main factors are:

1, the device

As the edge of engine and machine can not track well with, making the track does not run smooth, wavy, and the resulting edge of the gravity between the end plate so that there is no straight edge sealing, trimming adverse device ( within the device itself with the trimming knife); glue roller and conveyor belt rollers with the bad, lack of glue or uneven coating is widespread; trimming chamfering tool and the tool is often stressed is not good, not only need an extra man trimming, trimming required is difficult to ensure quality. In short, due to equipment commissioning, repair and maintenance of the level of poor quality due to the most common, the most lasting.

2, plate

As a substrate board, the thickness of the standard deviation generally can not, mostly positive tolerance, and often beyond the tolerance range (permissible tolerance range 0.1 ~ 0.2mm); flatness is also not up to standard. This makes the clamping surface of the track turn distance (substrate thickness) difficult to grasp, the distance is too small is likely to cause the weight of too tight, stress increases, resulting in open plastic; not too tight board spacing, edge banding can not be guaranteed and board-side solid combination.

3, the machining accuracy

During processing, the processing error comes mainly from the material and cut open. Systematic errors due to equipment and workers processing error, making the end can not reach the level of the workpiece, and the adjacent surface can not remain vertical, so when the edge of the edge is not full contact with the face plate, seal cracks or finished side exposed substrate after affect the appearance. What is more, the substrate occurs in the chipping process, it is difficult to rely on the edge of the cover

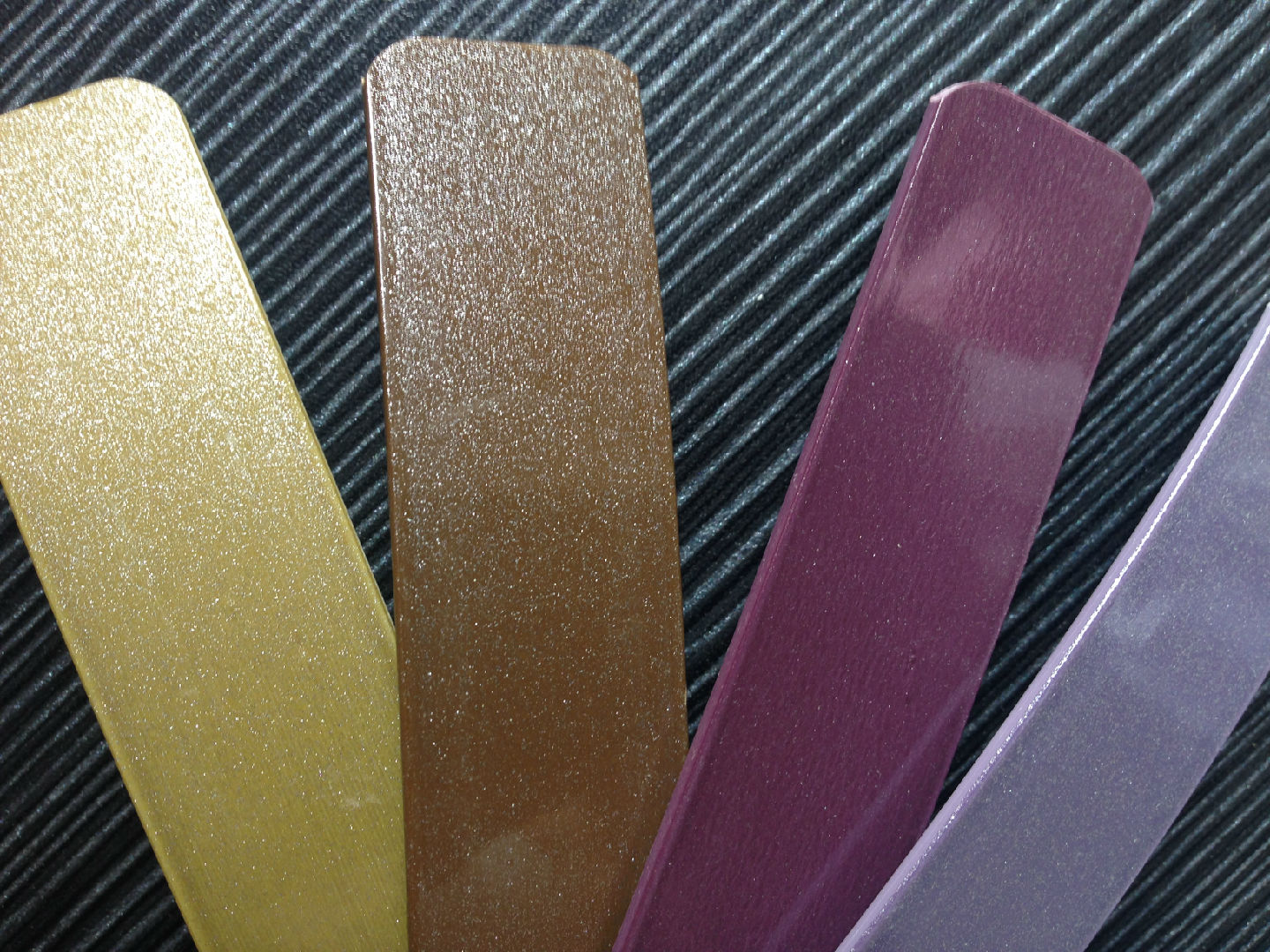

4, sealing materials

Edge PVC edge banding material mostly, greatly influenced by the environment. Winter hardening, decreased affinity of the rubber, together with a longer storage time, the surface of aging, the adhesive strength of the adhesive on the lower. For a small thickness of the paper Edge, because toughness greater thickness is too small (such as thickness 0.3mm), resulting in uneven edge of the incision, the bonding strength is not enough and ineffective trimming defects, rework rate is high, the edge of the waste is also very serious. Using a special adhesive sealing edge hot-melt glue. The winter due to low temperatures, and strength to ensure the glue, glue on the slightly higher temperature. If too high, more than 190 ℃, glue too thin, thin layer, so when applied to the face plate has cooled, add Edge of temperature is also low, resulting in edge intensity decreased significantly. If the temperature dropped to 170 ℃, plastic is a bit thick, but the lower edge of the temperature, the plastic and strength is not enough. Temperatures were lower, plastic will not melt well. In production, this conflict is very prominent, it is difficult to solve. Coupled with their laminated plastic substrate and edge quality, and with each of the three adaptability and affinity between the conditions, all affect the quality edge.